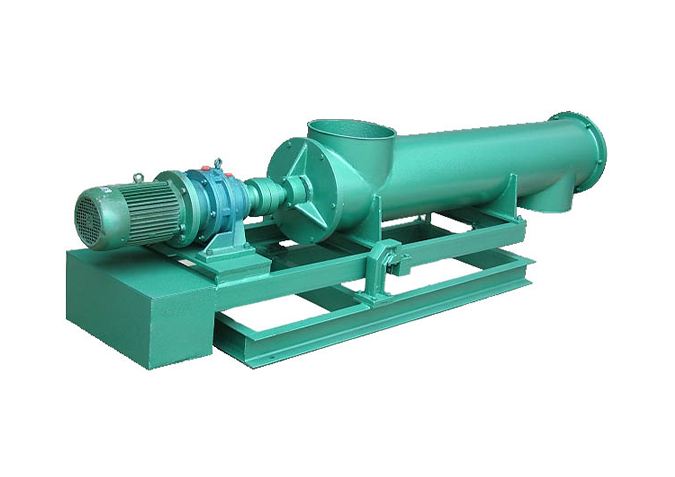

JGC-40 type weighing belt feeder is a feed measuring equipment integrating belt feeder, electronic belt scale, frequency conversion electronic control, widely used in metallurgy, electric power, coking, chemical industry, building materials, wharf and other industries.

1. Product details

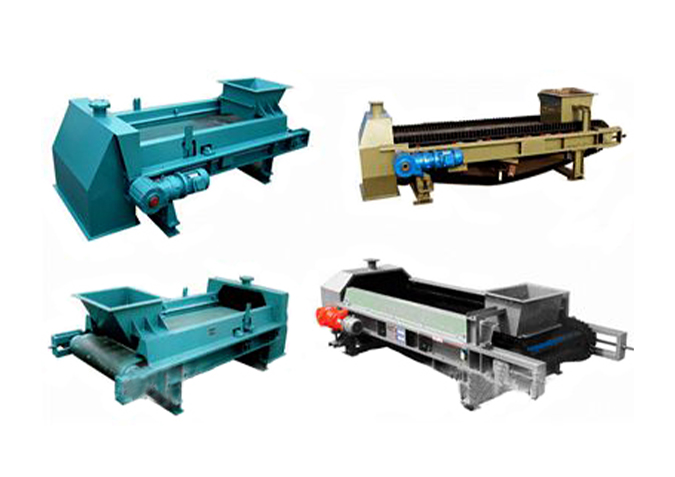

DEL/DEM quantitative feeder is our company's latest patented technology, high measurement accuracy, accuracy stability, small maintenance, easy maintenance, automatic operation, fully absorb the most advanced technology production of the sixth generation of frequency control quantitative feeder, various indicators exceed the domestic similar products to reach the international advanced level, to have high precision, reliable performance characteristics, Used for conveying bulk materials.

2.Principle

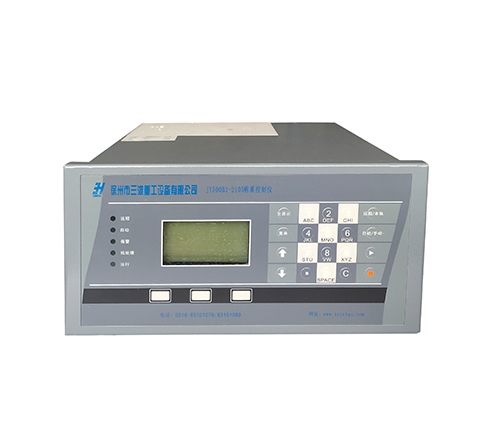

The transmission of the emperor load and speed signal to the microprocessor control measurement, control and adjustment system for processing, and constantly to the actual rate and set to the rate of the section, so as to control the speed of the feed rate to maintain at a constant level.

3.System characteristics

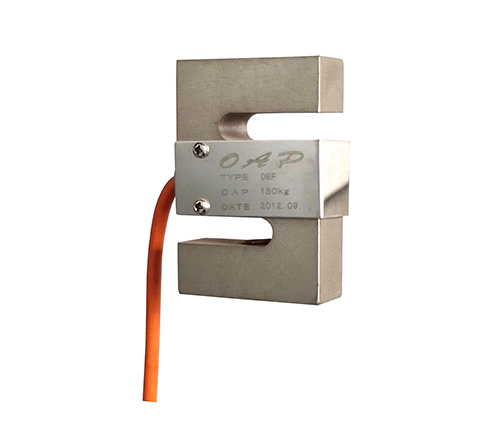

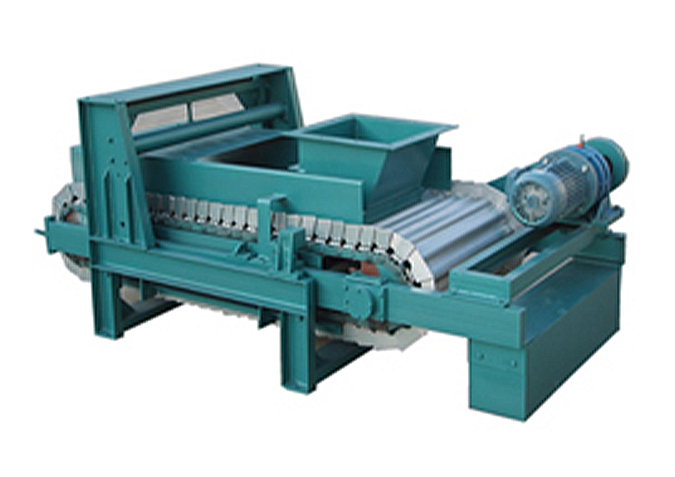

A high-resolution weighing sensor with a minimum displacement of 0.1mm ensures accurate measurement.

High resolution digital pulse side speed sensor to ensure accurate speed value;

Gravity automatic tensioning device to ensure constant belt tension, avoid belt slip and excessive tension;

Belt automatic correction device to avoid belt deviation and affect the production;

The plow scraper will clear the sundries on the lower belt to one side to avoid sundries between the belt and the roller surface to damage the belt;

Belt inside and outside the scraper to avoid belt sticking and tare change;

Without assistance, convenient belt replacement, simplified maintenance;

Automatic aligning bearings are adopted for the main and slave rollers, so it is very convenient to install and adjust.

4 customer selection

The roller or roller is coated with rubber

Hemline belt

High temperature belt

Detachable cover

Suitable for different material feeding hopper

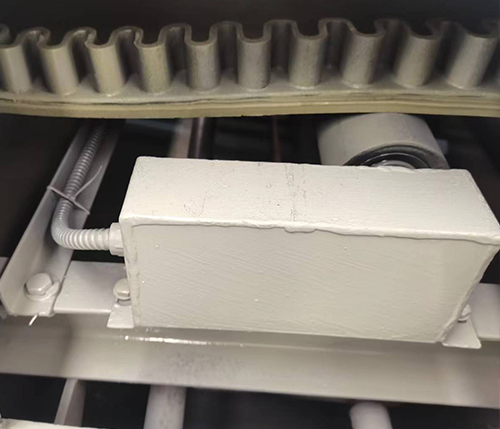

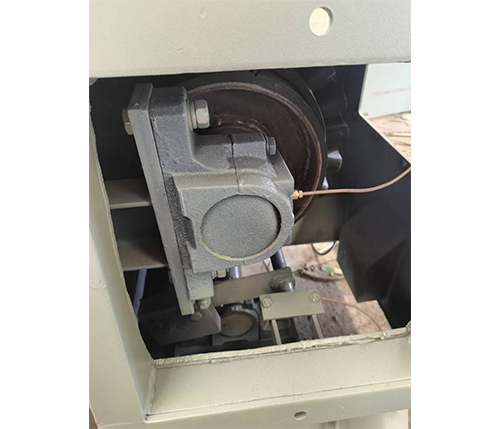

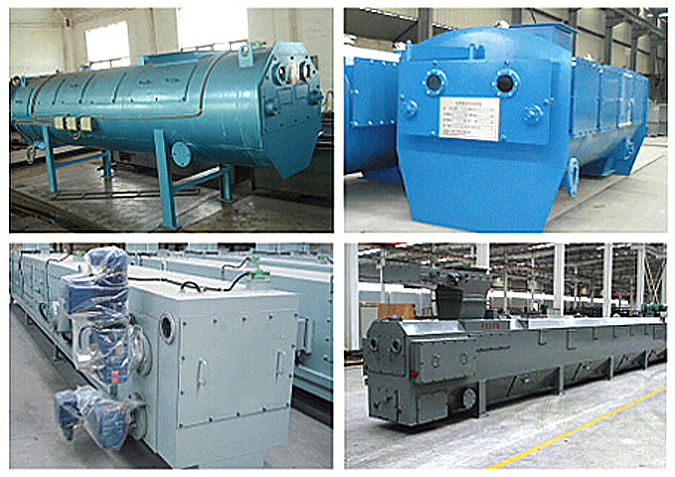

5. Use photos on site

6、 Product parameters

The actual feeding accuracy of various bulk materials is better than the set feeding rate of ± 0.5%

The feeding rate is approximately 50kg/h-2000t/h

Conveying bandwidth: 500mm-1800mm

Roller Centre-to-centre distance: ≥ 1300mn-5000mm, plug-in system is adopted

Output interface: Multiple options, can be connected to DCS system